With the rapid improvement of the technical level of liquid silicone, the application range of liquid silicone is becoming more and more extensive. In turn, this has attracted more people to explore this vast market. However, the resulting increase in uncertainty of choice and uneven quality also follow. JVTECH has been focusing on the field of liquid silicone for more than 20 years. With rich experience and strong technical strength, it has already formed a complete set of its own processes to ensure the provision of efficient, high-quality, and cost-effective products and services to facilitate customers. So when your project needs are in line with our expertise, we will help you achieve it efficiently. Let’s take a look today at how JVTECH realizes this for you:

Table of Contents

Toggle1.Before Project Preparation

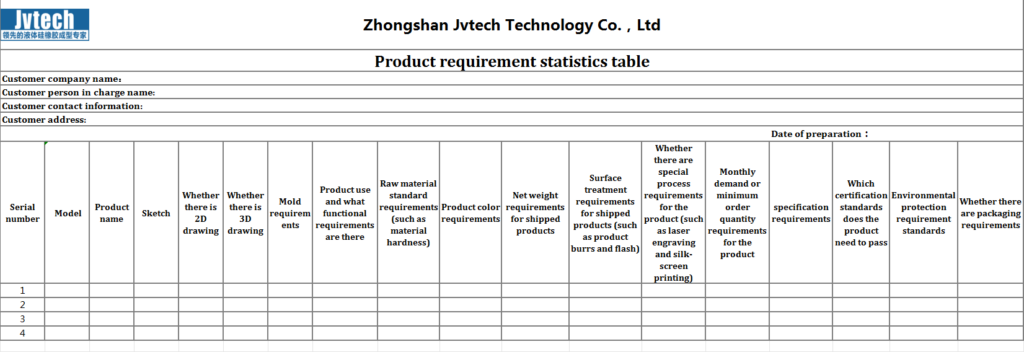

First, in the first stage: the initial project demand collection stage, we need to sort out the product applications of customers, including the use environment, the connection of upper and lower assembly parts, product testing standards, monthly demand and annual demand, and other information. These conditions will help us quickly lock in material and structure evaluations. It is also the basis for making a project evaluation plan according to demand. If you don’t have the above materials and don’t know how to prepare them, that’s okay. We will give you a plan for reference. The specific example is as follows:

Of course, if you have all of these, then we will quickly move on to the next link.

2.Early stage of project

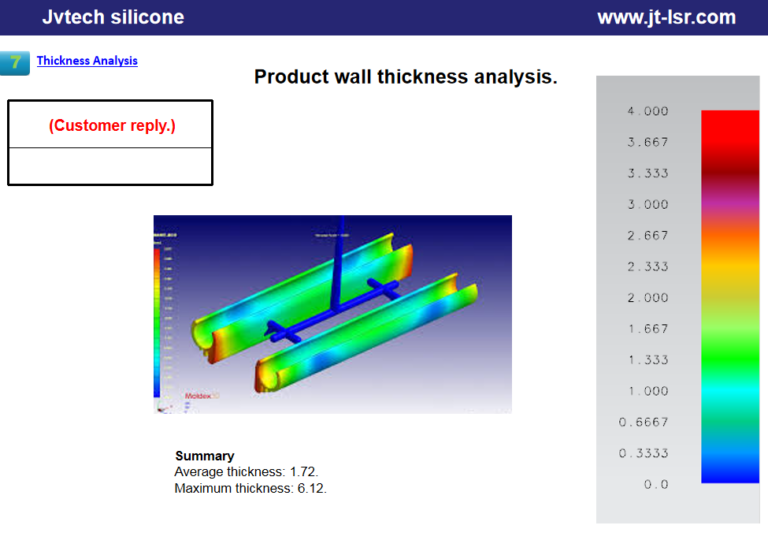

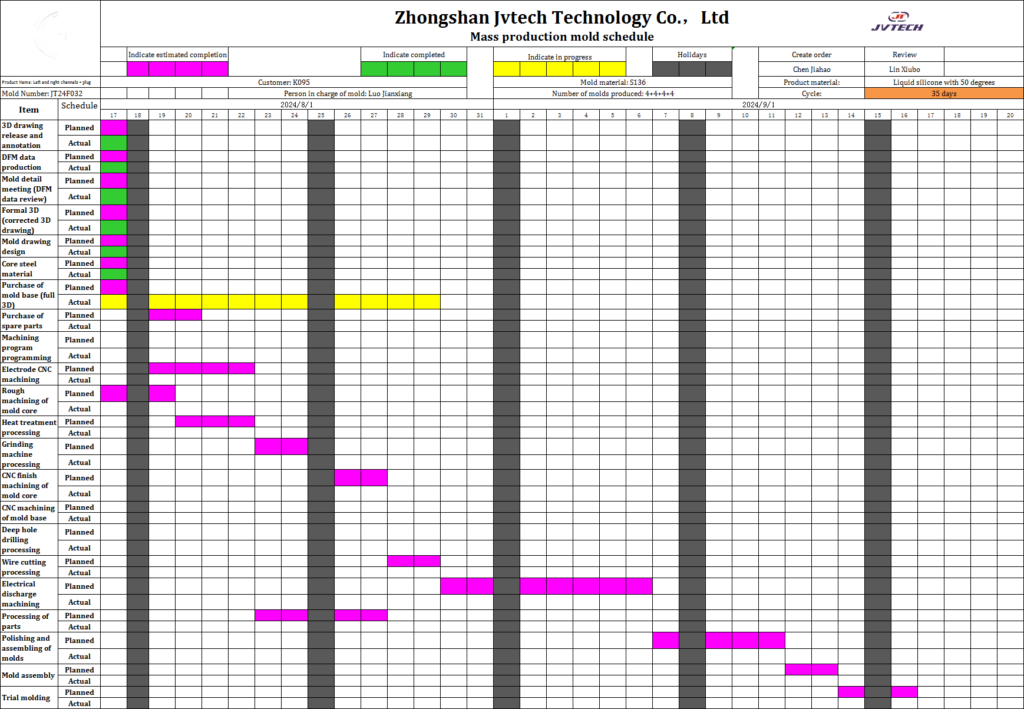

The structural coordination stage in the early stage of the second stage represents the official start. We will have a professional engineering and business team to serve you, integrate and complete product information, output a DFM report corresponding to the information, formulate a delivery plan and risk prediction, and formulate a risk preparation plan to ensure the on-time and safe delivery of the project. These reports will also be sent to you simultaneously, allowing you to predict problem points and avoid risks in advance before the project starts, thereby reducing research and development costs.

3.Mid-stage of project

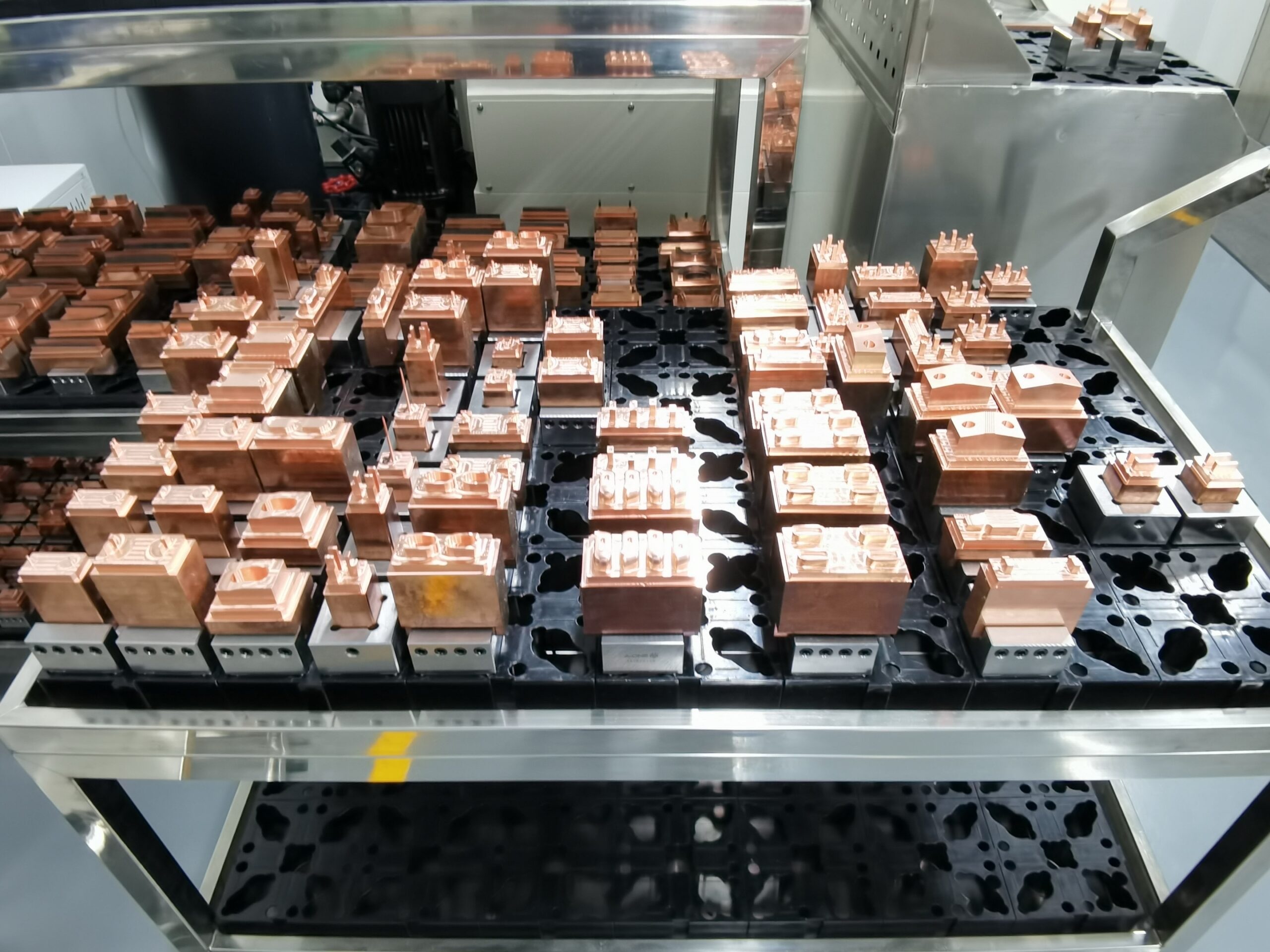

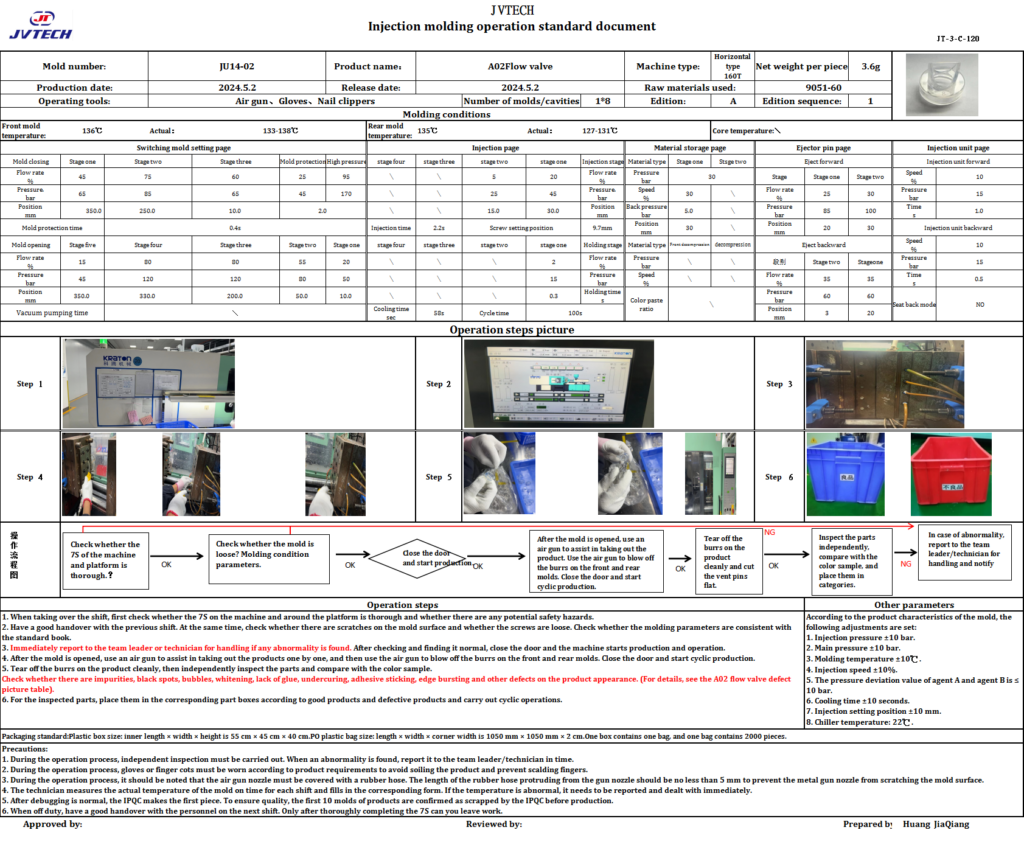

After the completion of the preliminary work, it officially enters the sampling and trial production stage. We will regularly output the progress of the project to ensure the achievement rate of T0. T0 is the most important link. We will predict the design change space and reserve tolerances according to actual needs to ensure the minimum design change workload. Adjustments are made to achieve mass production and delivery effects with low cost and high efficiency, so that delivery can be smoothly completed at T1. All specific executions are aimed at mass production at T3.

4.At the end of the project

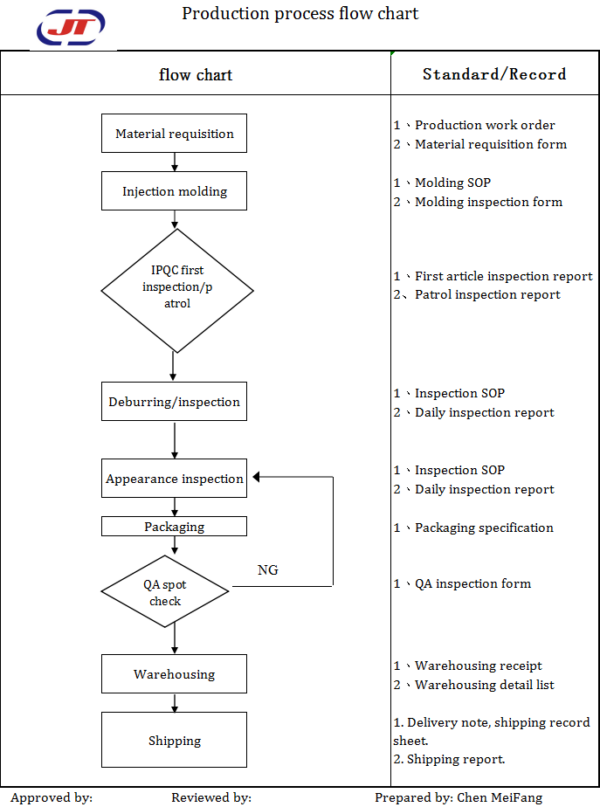

Finally, at the end of the project, we will take stable SOP mass production quality as the result orientation and judge the project success rate. Persistently, aiming at realizing sustainable optimization of production processes, we will make cost reduction plans with guaranteed quality and quantity to empower customers.

5.Project review

Finally, in the project review, we will fully understand the extensibility of the client’s project, such as size, same structure, style, and so on. Then we help customers modularize the project to achieve high efficiency, high quality, and high cost performance. Let our customers always stay ahead in the industry.

The above content is all real cases of JVTECH and relevant copywriting that has been practically verified. If friends are interested in this aspect, welcome to call or visit JVTECH on site. After all, instead of making mistakes everywhere, it is better to accurately find professional people. Time cost is the most un-wastable and precious. JVTECH believes that our strengths can meet your needs.