In today’s material world, silicone has attracted much attention with its unique properties and wide range of application fields. Among them, liquid silicone and solid silicone each have their own characteristics and provide diversified solutions for different needs. So what are the differences between liquid silicone and solid silicone? What are the differences in molding processes? Let’s find out:

Table of Contents

Toggle1.Classification by form

a. Liquid silicone: It is in a liquid state before curing and has fluidity. The raw material has high transparency. The finished product has no obvious mold joint line, and the burr is slight (not easily noticeable by the naked eye). The product has an injection port.

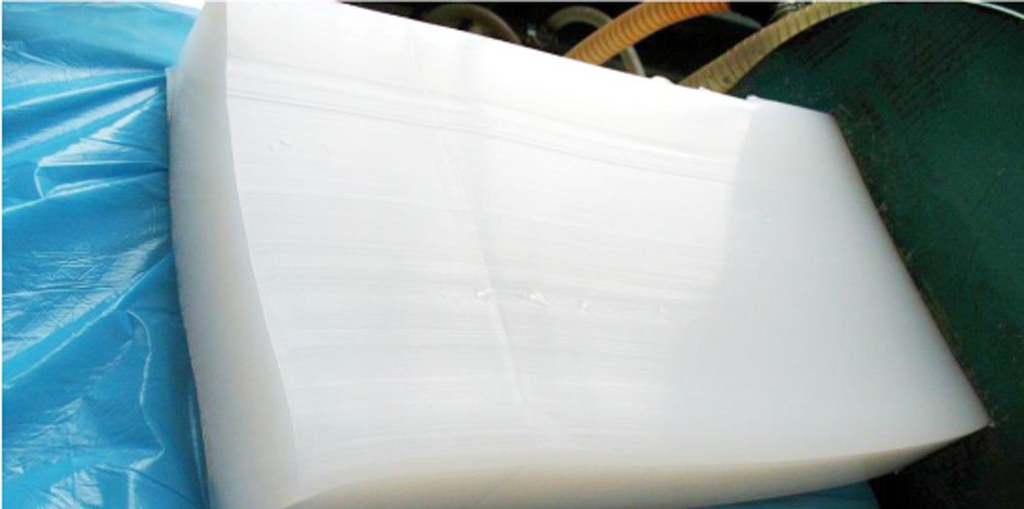

b. Solid silicone: It is in a solid state and has no fluidity. The raw material has low transparency and is generally milky white and translucent. The burr at the mold joint of the finished product is more obvious, and the product has no injection port.

2.Classification by performance

a.Liquid silicone: Compared with solid high-temperature vulcanized silicone, it is a liquid glue with good fluidity, greater safety and environmental protection. It can fully meet food-grade requirements, and has higher adhesion and better activity.

b. Solid silicone: Solid silicone is a saturated polymer elastic material. It has characteristics such as high temperature resistance, cold resistance, solvent resistance, toughness resistance, anti-adhesion, electrical insulation, and chemical resistance. However, its adhesion is relatively poor. It is usually used in daily necessities, industrial miscellaneous parts and automotive parts.

3.Classification by processing method

(1) Differences in raw material processing

a.Liquid silicone: Mostly two-component (AB) liquid silicone rubber, also known as AB glue. The raw material processing uses platinum as a vulcanization catalyst. The general ratio of AB agent is 1:1 or 10:1, depending on the formula of the raw material manufacturer. The packaging method is mostly 1:1 liquid barrels, and there are options ranging from 10KG/20KG/25KG to 200KG. After delivery, the raw material can be directly molded without adding vulcanizing agent or any processing.

b. Solid silicone: It is a single-component silicone rubber, mostly vulcanized by organic peroxides. The raw materials are boxed in solidified rubber blocks. Later, the silicone product processing manufacturer adds auxiliary materials such as mixing and curing agent according to needs to complete the raw material processing before molding.

(2) Differences in manufacturing processes

a.Liquid silicone: Precise control of the feeding dose, and the raw material is injected and molded in a closed mold. The size is more precise, the tolerance is small, the burr is slight, the appearance is more refined, and the degree of automation is high. A lower molding temperature of up to 130°C can be accepted.

b. Solid silicone: The mold is closed for molding only after manually cutting and placing the raw materials. The size is difficult to control, the burr is large, and the mold joint line needs to be removed by itself. High temperature molding above 180°C is required.

(3) Differences in molding methods

a.Liquid silicone: The most commonly used injection molded liquid silicone (LSR): The full name is injection molded liquid silicone, and the vulcanization equipment is an injection molding machine. The process flow of the injection molding machine is very simple. The product has high precision, high output (A/B glue is molded in a few seconds at a certain temperature), saves manpower, electricity, materials and many other advantages. It can produce all products produced by high-temperature glue. It is a mainstream of the development of silicone materials in the future. Liquid silicone is a high-transparency and high-safety food-grade material. No vulcanizing agent or other auxiliary materials are added during molding, and it is molded by sealed feeding.

b. Solid silicone: After a block of solid raw materials is mixed by a mixer, the cutting machine cuts it to a suitable size and thickness for the product and mold, and then puts it into the mold and molds it at a certain temperature under a pressure molding machine. When demolding, it is similar to plastic products, and the mold also needs to be cleaned. Solid silicone is a transparent material. When molding, a vulcanizing agent needs to be added to accelerate the vulcanization molding time, and it is molded by open mold feeding.

(4) Differences in process flow

a.Liquid silicone: Fully automated production; short production cycle; no need for pre-processing of materials, more efficient and saves labor.

b. Solid silicone: It requires processes such as batching, rubber refining, rubber cutting, and manual feeding, and is relatively less efficient.

(5) Differences in safety

a.Liquid silicone: Since liquid silicone is completed from raw material processing to sealed packaging in a clean space or even a clean room, and the production stage is also molded by sealed feeding. Feeding to the mold cavity in a closed pipeline, the process is completely isolated from the outside world, which can be said to control the product cleanliness to the highest degree and prevent environmental pollution. The texture is highly transparent, pure and odorless, which can be said to be a guarantee of peace of mind from the inside out.

b. Solid silicone: It is also a silicone raw material. In a broad sense, solid silicone itself is also safe and non-toxic. The reason why it is slightly inferior to liquid silicone is mainly reflected in the cleanliness problems caused by the limitations of the processing process and the differences in environmental requirements between the two. In addition, the solid silicone has low transparency, which is easy to cause poor appearance or problems that impurities are not easily found. In addition, the raw material processing process of solid silicone needs to add additives such as vulcanizing agents, and there are often odors and other phenomena.

4.Classification by application prospects

a.Liquid silicone: Generally used in application fields such as baby products, kitchen products, and medical supplies that need to be in direct contact with food and the human body, or in high-precision fields such as optical lenses.

b. Solid silicone: Generally used in aspects such as daily necessities, industrial miscellaneous parts, and automotive parts that have relatively lower requirements for precision.

Liquid silicone is relatively easier to process than solid silicone. Due to the easy fluidity of liquid silicone, it can be molded, calendered, and extruded with lower energy consumption. This also means that liquid silicone has unique advantages in meeting high-precision production requirements. Of course, this also reflects its advantage of high production efficiency.

The liquid silicone injection molding machine has a very simple process flow (without the manual processes such as batching, rubber refining, cutting, and arranging materials in the high-temperature rubber process. Only one worker takes the product or automatically demolds). The product has high precision (all manual procedures are replaced by machines before molding). High output (A/B glue is molded in a few seconds at a certain temperature), saves manpower, electricity, materials, has low cost and high efficiency, is safe and environmentally friendly, and has many other advantages. It can produce all products produced by high-temperature glue and is the mainstream of silicone material development in the future.

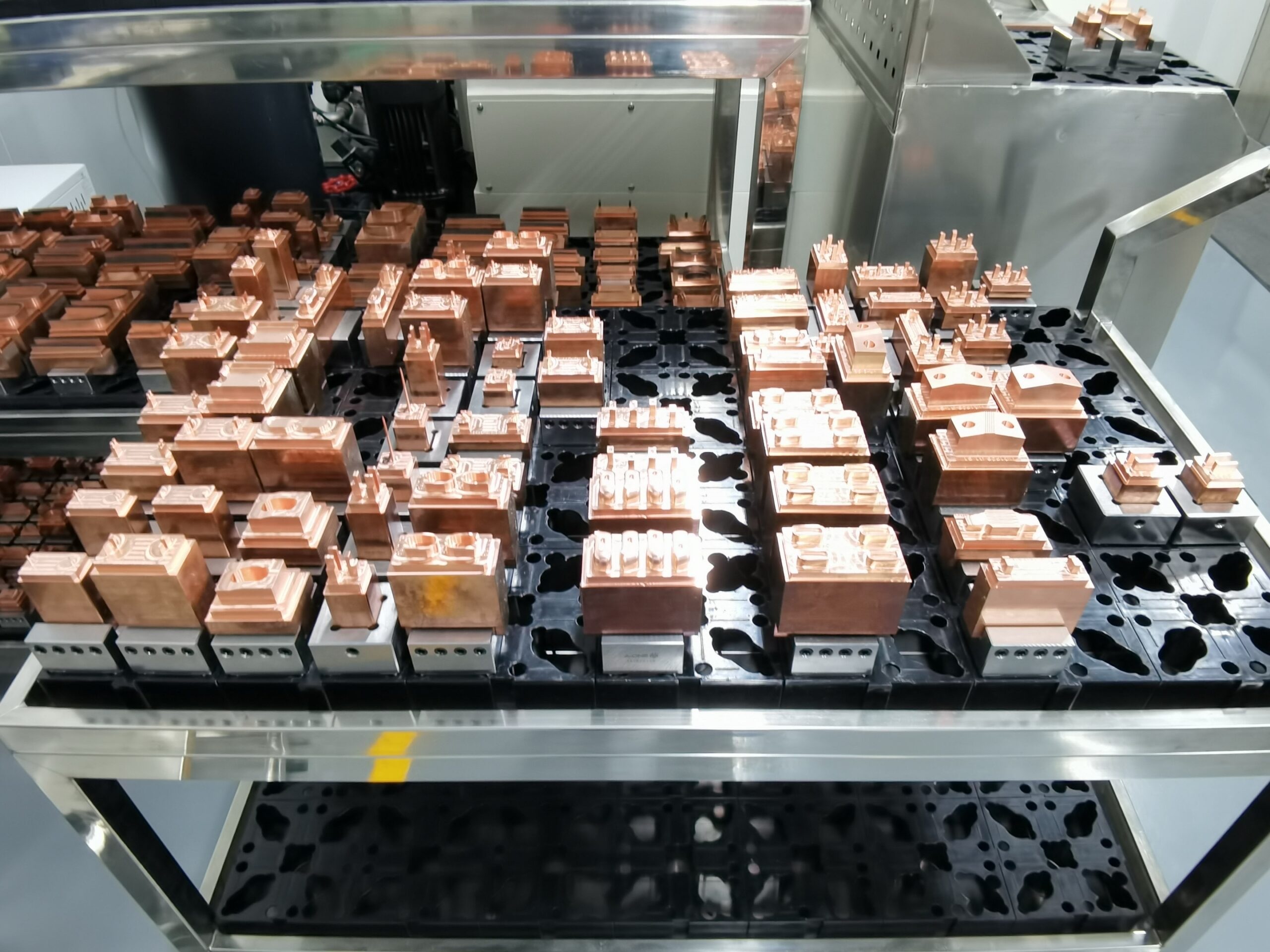

As a one-stop solution provider focused on liquid silicone manufacturing with more than 20 years of experience, JVTECH has now expanded its own factory building to more than 12,000 square meters. It has more than 70 professional LSR injection production equipment, automated production and molding equipment, and has advantageous technologies such as multi-material overmolding and two-color silicone molding. It has a 100,000-level dust-free inspection workshop, establishes an independent laboratory, and is equipped with various precision testing equipment to provide better quality services.

JVTECH adheres to the business philosophy of “being strong in management and winning positively”, and provides customers with the highest standard products and services. Thanks to the stable quality of the company’s products, perfect services, and highly competitive prices, the products are sold at home and abroad and all over the world, making it an industry leader in liquid silicone manufacturing solutions. At present, products are widely used in fields such as consumer electronics, medical devices, baby products, automotive waterproofing, optical LEDs, etc. The company has passed ISO9001, ISO13485, ISO45001, ISO14001 and IATF16949 quality management systems and strictly implements national and European standards for VOC control. It has more than 50 invention patents and utility model patents, and at the same time has obtained the recognition of high-tech enterprises.

Sometimes a gas gun is needed for LSR manufacturing. If the gas in the air compressor is not clean, it will pollute the mold.

Countermeasure: Regularly check the working status of the dryer of the air compressor and replace the filter within the safe cycle of the dryer. Keep the air dry and clean!