Life Science / Medical Injection Molding

Setting a New Standard in Medical Device Manufacturing

In the manufacturing of modern medical devices, Liquid Silicone Rubber (LSR) has become indispensable. Our company leverages advanced LSR mold manufacturing, automated molding production lines, and ISO Class 8 cleanroom management to provide high-quality, reliable contract manufacturing services for global medical brands.

4 Reasons to Turn to the Liquid Silicone for Medical Production Parts

1.Biocompatibility:

LSR is highly biocompatible, meaning it is well-tolerated by human tissue and does not cause adverse reactions, making it ideal for medical implants and devices that come into contact with the body.

2.Chemical Resistance:

LSR resists various chemicals, including acids, bases, and solvents, ensuring durability and safety in harsh medical environments.

3.Temperature Resistance:

It maintains its properties across a wide temperature range, from extreme cold to high heat, suitable for sterilization and diverse medical applications.

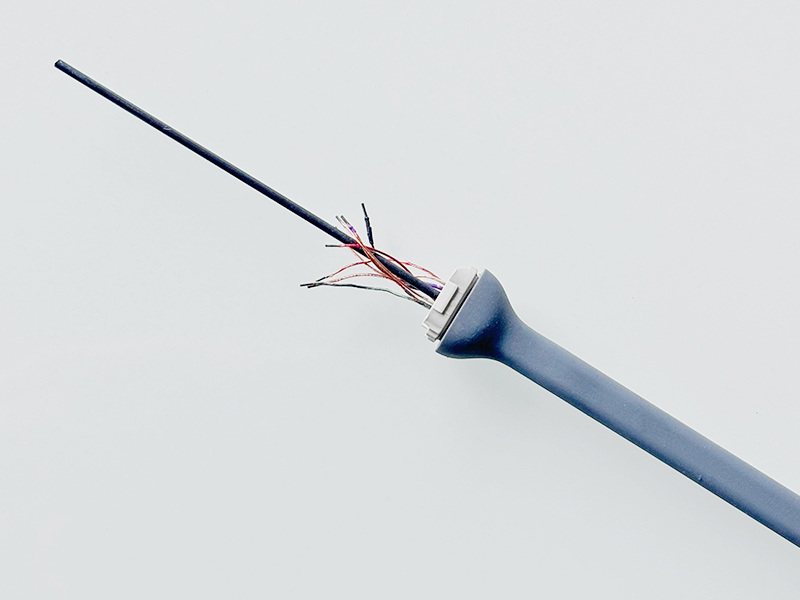

4.Overmolding Capabilities:

LSR can be overmolded onto materials like plastic, glass, and metal, allowing the creation of complex, multi-material medical devices that enhance functionality and user comfort.

Application of Liquid Silicon Rubber in Medical

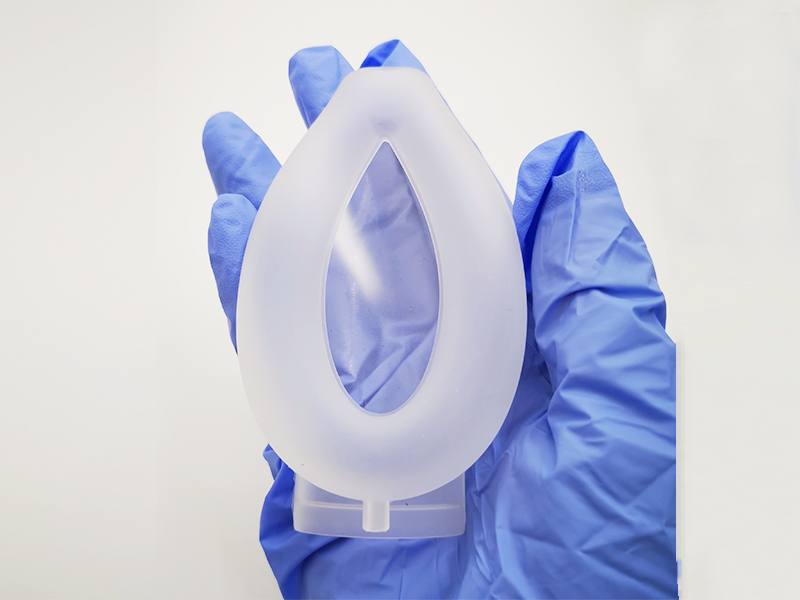

Medical Implants

LSR is used in various implants such as catheters, pacemaker components, and feeding tubes due to its biocompatibility and flexibility.

Medical Implants

LSR is used in various implants such as catheters, pacemaker components, and feeding tubes due to its biocompatibility and flexibility.

Surgical Instruments

Its sterilizability and durability make it ideal for surgical tools, syringe components, and valve seals.

Surgical Instruments

Its sterilizability and durability make it ideal for surgical tools, syringe components, and valve seals.

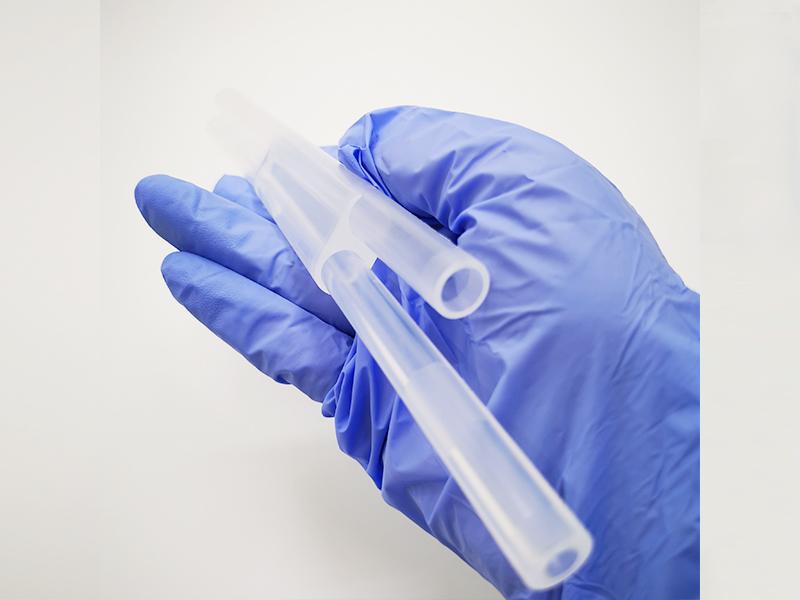

Respiratory Devices

LSR is widely used in respiratory masks and tubing, benefiting from its flexibility and chemical resistance.

Respiratory Devices

LSR is widely used in respiratory masks and tubing, benefiting from its flexibility and chemical resistance.

With high-precision LSR medical device injection molding, we whip up perfectly uniform components right out of the machine – it’s like magic! The flexible nature of LSR makes it the perfect match for valves, diaphragms, and other silicone medical products that need to bend and flex under pressure, but seal up tight when things calm down. And because LSR is so chill and has top-notch physical properties, it’s ideal for components that mingle with chemicals, blood, and bodily fluids – think connectors, seals, gaskets, and impellers in dialysis filters and infusion pumps.

Multi-component molding can make part quality and consistency more better. Complicated assemblies no need anymore, we can directly bonding LSR onto plastics or metals, so can save time and costs for assembly. Over-molding LSR onto surgical tool handles make them more easy to grip, more accurate and comfortable, and also can be sterilized easily. Multi-component valves, washers, and seals also become better because of LSR’s good material properties and the less assembly steps of LSR 2-Shot medical device injection molding or over-molding.

The Medical Projects We Have Done.

We are a reliable partner.

Our production processes are certified by ISO 13485 and other international standards, ensuring each product meets the strictest medical requirements. From surgical instruments to respiratory masks, our LSR products have earned unanimous praise for their superior performance.

A high-quality production environment and strict quality control systems are the foundation of our continuous innovation and pursuit of excellence. Whether for customized production or large-scale manufacturing, we provide the best solutions.

_01-724x1024.jpg)

ISO 13485

ISO 9001

ISO 45001

ISO 14001

experienced

Focus on OEM development of liquid products for more than 10 years.

Quality control

According to the ISO13485 standard, it has a 100,000-class dust-free workshop.

Low unit costs

We have been promoting automation to reduce labor costs.

Lead time

The mold can be completed within 7 days and the urgent order can be received.

Project insight

Core Service

LSR/LIM Injection Molding

LSR molding is different from solid compression molding, with fast productivity and high precision. We also support multi-cavity mold design.

LSR 2K Molding

Jvtech has years of experience of producing multi-component molds and parts (2K or more).

Overmolding

We have a stable R&D process for multi-cavity molds to minimize your production costs.

Quality System

Strict implementation of ISO system standards, professional testing equipment to control product quality.

Volume Production

24-hour operation dust-free production workshop equipped with robotic pick-up, intelligent material storage system.

Mould Manufacturing

Support rapid mould, accurate mold flow analysis, and quickly enter according to DFM documents.

Stage T0.

How it works

Easy step

Our international team of engineers works with you to make your product ideas a reality through manufacturing technologies.

Upload Desgin

Submit the important details about your project.

DFM Review

We perform a design analysis to optimize your parts.

Confirm Quote

We begin working with our team to make your ideas a reality.

Production Starts

Your custom parts are delivered straight to your doorstep.

Let's start talking with us

Our value

Let’s build the future with innovation.

Jvtech has a team of experienced and skilled designer, engineer and technician. High quality standard, competitive price, on time delivery and responsible afer-sales service are the principle that we follow to develop the mutual trust and confidence with our domestic and international clients.

If you have any new design of products need to be tested and put on the market, please do not hesitate to contact us. We will get back to you as soon as possible.