Automotive Injection Molding

Electric vehicles are the future.

The future trend of new energy vehicles is poised for rapid growth. With increasing environmental awareness and government support, the market share of new energy vehicles will continue to rise. Their use of clean energy has a positive impact on the environment, reducing emissions and helping to improve air quality and mitigate climate change. Additionally, the promotion of new energy vehicles will stimulate the development of related industries, create more job opportunities, and have a positive impact on economic growth.

4 Reasons to Turn to the liquid silicone for Automoblie Production Parts

1.Chemical Stability:

Liquid silicon is stable in extreme temperature and harsh environment, and is suitable for the operation of automobiles in various climatic conditions.

2.Chemical Resistance:

Flexible texture, not easy to burst, excellent explosion-proof performance.Non-toxic, low density, stable performance, high light transmittance of 92% and excellent weather resistance.

3.Temperature Resistance:

Temperature resistance range: -40~250℃, and resistance to sudden cooling and thermal shock.

4.Overmolding Capabilities:

LSR can be overmolded onto materials like plastic, glass, and metal, allowing the creation of complex, multi-material medical devices that enhance functionality and user comfort.

Automobile battery

Sealing of battery module: LSR is used to seal the joint and shell of battery module, which can prevent moisture and dust from entering the battery.

Medical Implants

LSR is used in various implants such as catheters, pacemaker components, and feeding tubes due to its biocompatibility and flexibility.

Liquid silicone lens

The advantages of liquid silicone lens are better elasticity and impact resistance, high and low temperature resistance, aging resistance and sealing performance.

Surgical Instruments

Its sterilizability and durability make it ideal for surgical tools, syringe components, and valve seals.

EV Motor

In EV motors, LSR can be used for motor end sealing, outlet sealing and winding insulation and fixation. LSR has excellent insulation performance. This is helpful to improve the electrical safety of the motor, reduce the risk of leakage and short circuit, and ensure the stable operation of the whole system.

Respiratory Devices

LSR is widely used in respiratory masks and tubing, benefiting from its flexibility and chemical resistance.

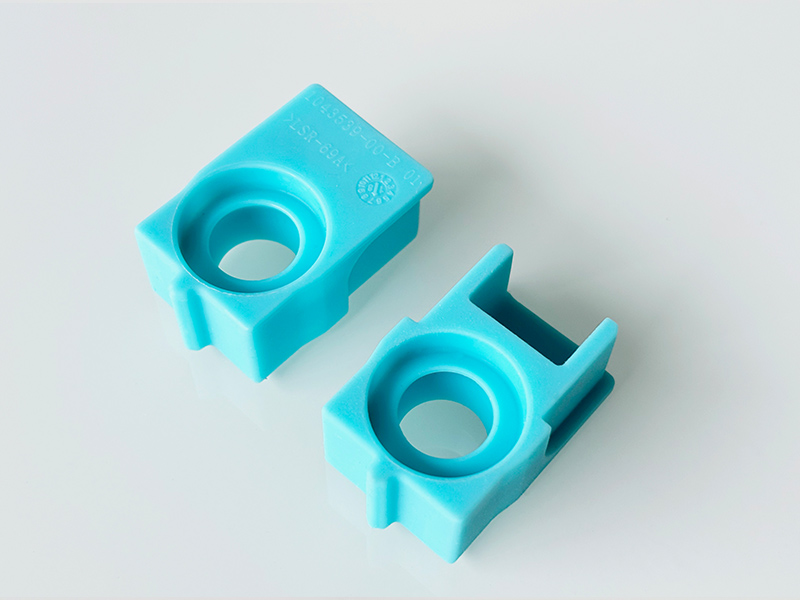

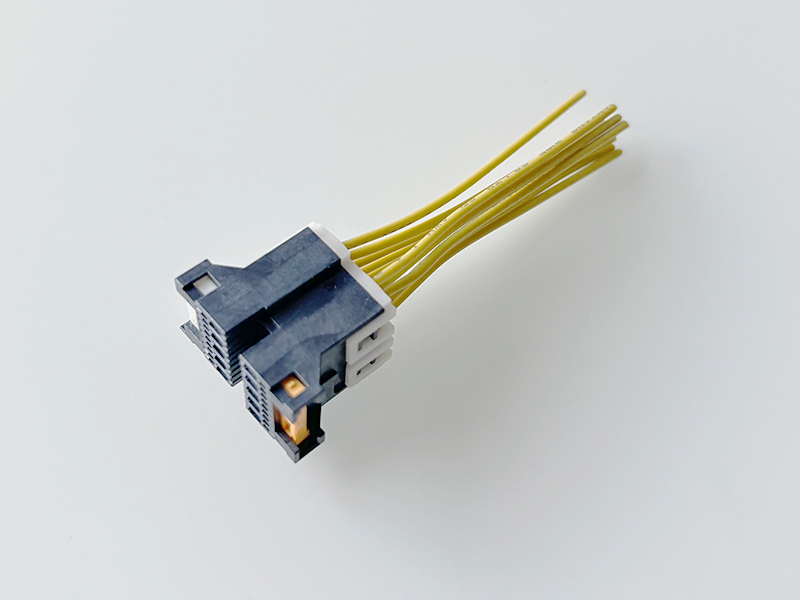

The projects we have done.

We are a reliable partner.

Our production process has produced auto parts according to IATF16949 standard, and the certificate is expected to be issued in October 2024 to ensure that each part meets the industry requirements. From sealing rings to automobile lenses, our LSR products have won unanimous praise for their excellent performance.

High-quality production environment and strict quality control system are the basis of our continuous innovation and pursuit of Excellence. Whether it’s customized production or large-scale manufacturing, we provide the best solution.

_01-724x1024.jpg)

ISO 13485

ISO 9001

ISO 45001

ISO 14001

experienced

Focus on OEM development of liquid products for more than 10 years.

Quality control

According to the ISO13485 standard, it has a 100,000-class dust-free workshop.

Low unit costs

We have been promoting automation to reduce labor costs.

Lead time

The mold can be completed within 7 days and the urgent order can be received.

Project insight

Core Service

LSR/LIM Injection Molding

LSR molding is different from solid compression molding, with fast productivity and high precision. We also support multi-cavity mold design.

LSR 2K Molding

Jvtech has years of experience of producing multi-component molds and parts (2K or more).

Overmolding

We have a stable R&D process for multi-cavity molds to minimize your production costs.

Quality System

Strict implementation of ISO system standards, professional testing equipment to control product quality.

Volume Production

24-hour operation dust-free production workshop equipped with robotic pick-up, intelligent material storage system.

Mould Manufacturing

Support rapid mould, accurate mold flow analysis, and quickly enter according to DFM documents.

Stage T0.

How it works

Easy step

Our international team of engineers works with you to make your product ideas a reality through manufacturing technologies.

Upload Desgin

Submit the important details about your project.

DFM Review

We perform a design analysis to optimize your parts.

Confirm Quote

We begin working with our team to make your ideas a reality.

Production Starts

Your custom parts are delivered straight to your doorstep.

Let's start talking with us

Our value

Let’s build the future with innovation.

Jvtech has a team of experienced and skilled designer, engineer and technician. High quality standard, competitive price, on time delivery and responsible afer-sales service are the principle that we follow to develop the mutual trust and confidence with our domestic and international clients.

If you have any new design of products need to be tested and put on the market, please do not hesitate to contact us. We will get back to you as soon as possible.

Professional Expert

Technology & Innovations

Premium Support

Frequency Asked Questions of Automotive Injection

What are the common applications of liquid silicone rubber (LSR) molding in the automotive industry?

LSR molding is widely used in the automotive industry to produce a variety of parts, including seals, gaskets, O-rings, electrical connectors, keypads, and lighting components. LSR’s excellent thermal stability, chemical resistance, and electrical insulation properties make it ideal for these demanding applications.

How does LSR molding compare to traditional automotive plastic molding?

LSR molding offers several advantages over traditional automotive plastic molding, such as greater design flexibility, tighter tolerances, and improved part consistency. LSR parts also exhibit superior resistance to heat, chemicals, and UV radiation, making them more durable in harsh automotive environments.

What are the benefits of using LSR assembly in automotive manufacturing?

LSR assembly allows for the creation of complex, multi-material parts with integrated functionality. This can reduce the number of individual components required, simplifying the assembly process and improving overall product reliability. LSR’s bonding capabilities with various substrates, such as plastics and metals, make it ideal for automotive assembly applications.

What role does automotive injection molding play in LSR part production?

Automotive injection molding is the primary method for producing LSR parts. It involves injecting a two-part liquid silicone rubber mixture into a mold, where it cures and solidifies into the desired shape. Precision injection molding ensures consistent part quality and dimensional accuracy, which are critical for automotive applications.

How can LSR molding contribute to lightweighting in automotive design?

LSR’s low density and ability to replace heavier materials like metals and thermoplastics can contribute to lightweighting efforts in automotive design. Lighter vehicles offer improved fuel efficiency and reduced emissions, making LSR molding an attractive option for environmentally conscious manufacturers.

What are the future trends in automotive LSR molding?

The future of automotive LSR molding is bright, with ongoing advancements in materials, processing techniques, and automation. We can expect to see increased adoption of LSR in electric vehicles (EVs) due to its excellent electrical insulation properties and thermal management capabilities. Additionally, the development of new LSR grades with enhanced properties, such as flame retardancy and self-healing capabilities, will further expand its applications in the automotive industry.