Liquid silicone is a non-toxic, heat-resistant, highly resilient, and soft thermosetting material. Its rheological behavior is mainly characterized by low viscosity, rapid curing, shear thinning phenomenon, and a relatively high coefficient of thermal expansion.

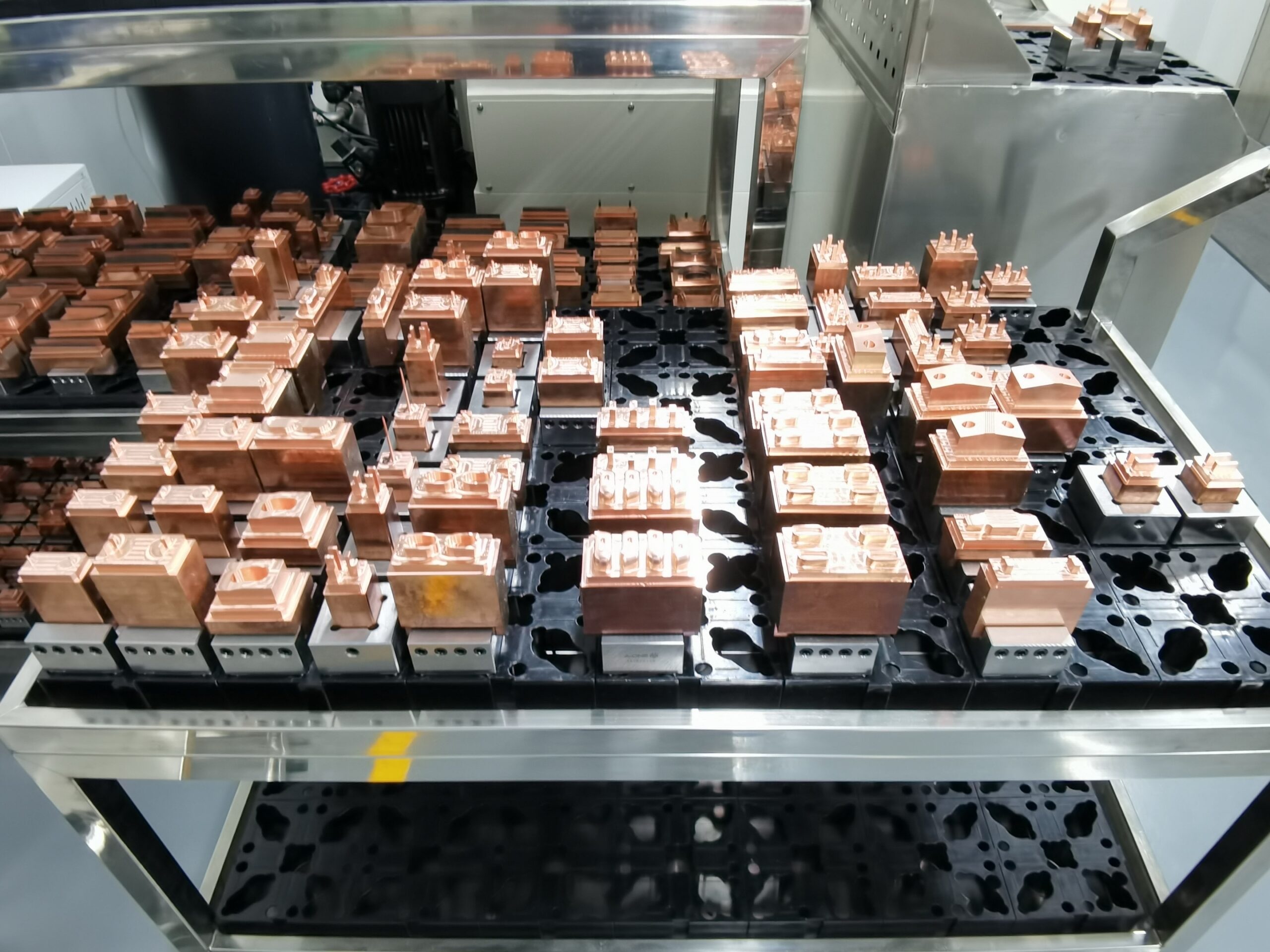

Liquid silicone is a two-component rapid curing material using platinum (Pt) as a catalyst, divided into Component A and Component B. The two are controlled by a quantitative device in a 1:1 ratio and then fully mixed through a static mixer. It can be molded by injection molding, which has the advantages of mass production, rapid cross-linking and curing, and less waste.

Liquid silicone products have excellent temperature resistance, weather resistance, corrosion resistance, superior electrical insulation, excellent elasticity, outstanding waterproof performance, are safe, non-toxic, and harmless, and do not produce toxic substances when burned. Therefore, it has a wide range of applications. In health products, auto parts, mother and baby products, medical appliances, daily necessities, optical lenses, electronic miscellaneous parts, and sealing application products, liquid silicone is an irreplaceable material in the current production design.

Table of Contents

Toggle1.The processing and molding process of liquid silicone

-e1722913395301.png)

The main principle of liquid silicone molding is that silicon molecules (Si) and hydrogen molecules (H) undergo a cross-linking reaction (curing) under the catalysis of platinum (Pt) and high temperature. The molding process only requires three steps: [metering and mixing], [molding], and [curing and shaping].

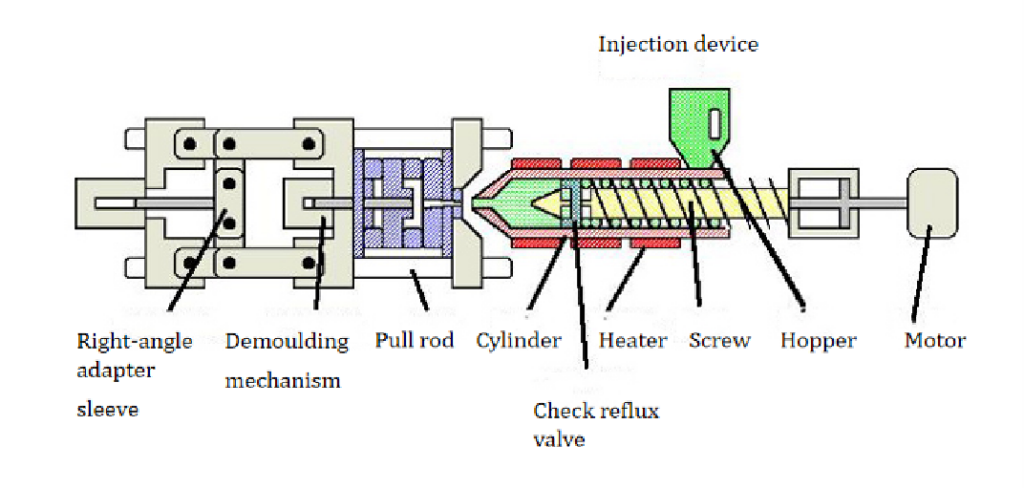

Liquid silicone has superior fluidity and good flexibility after molding in the mold, so it can complete designs with higher precision, which is beyond the reach of other types of materials such as plastics. Liquid silicone is usually injection molded by an injection machine, and its molding equipment is similar but not exactly the same as the processing equipment commonly used for thermoplastics.

Liquid silicone is a two-component liquid raw material, divided into Component A and Component B. The A and B components are precisely mixed in a 1:1 ratio using a mixing device. In addition, due to the colored design of some products, additional coloring pump sets and color metering devices for colored materials can be added. During use, A+B, additives, colorants, etc. are fully mixed in the static mixer and then introduced into the plasticizing system.

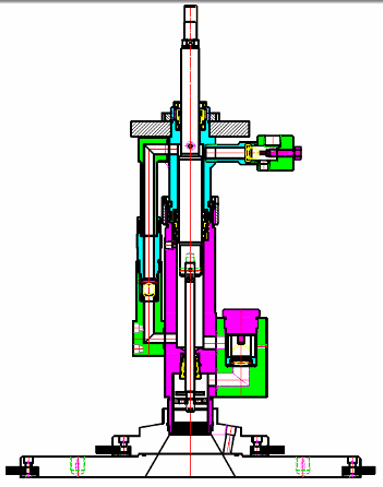

The special plasticizing screw for liquid silicone has the functions of homogenization and mixing. The mixture is introduced into the high-temperature mold through the screw, and the silicone material undergoes a curing reaction and rapid molding under the mold temperature of 170-200°C. When the liquid silicone mold uses a cold runner feeding system, it should be particularly noted that the runner should be kept at a low enough temperature. In addition, in order to avoid material leakage, a needle valve device is installed on the surface of the mold components. After the injection is completed, the needle valve immediately closes the injection nozzle.

2.Key points for high-precision molding of liquid silicone

2.1 Key components of the liquid silicone injection molding machine

- Due to the low viscosity of liquid silicone, the problem of material reflux and leakage that may occur during the processing needs to be considered.Therefore, special attention should be paid to the sealing of the injection screw.

- To prevent the premature curing of liquid silicone, it is best to use a needle valve type injection nozzle. When the injection is completed, the nozzle is immediately closed and a good heat insulation design is made.

- Mixing and metering devices for Components A and B.

2.2 Feeding system

The feeding system can be roughly divided into the following modes:

- Bidirectional pump: It can feed materials up and down, has a good voltage stabilizing effect, and can be controlled by the synchronous hydraulic and pneumatic mechanism connected between the A and B pumps. Therefore, the control measurement is more accurate and reliable.

- Unidirectional pump: General-purpose feeding system, can only feed materials in one direction.

- Measuring cylinder system: This system is mainly used in conjunction with unidirectional pumps.

- Check valve synchronous unidirectional pump: A unidirectional pump with a check valve and can be used synchronously.

2.3 Mold design

In the design considerations of the mold, there are generally the following forms:

- Hot runner: This form wastes more materials, but the advantage is simple design and low cost, and it is mostly used in large products.

- Cold runner with needle valve: The advantage of this form is that it can be automated and has a short molding cycle.

- Cold runner without needle valve: Due to the expansion characteristics of liquid silicone itself, the finished product of this form cannot maintain accurate side margins in the mold. The disadvantage is obvious and it is not recommended to use.

In order to keep the liquid silicone at the proper low temperature and fluidity, the cold runner is best to adopt a closed system. In the injection processing cycle, the closed system uses [sealing pins] or [needle valves] in each runner to control the accurate metering of liquid silicone. Due to the significant thermal expansion characteristics of liquid silicone, the shrinkage rate is 2-4% (the reaction curing temperature is 150°C), and liquid silicone has the characteristic of deformation under pressure.

Therefore, the following key points should be noted in the mold design:

① To avoid turbulence and jetting, smaller feed inlets should be used, such as small pin points or wing-shaped small gates;

② Use T-shaped guide pins instead of column-shaped guide pins;

③ Install heat insulation devices, such as heat insulation plates;

④ Do not use rust inhibitors/oils containing polymerization inhibitors. Instead, toluene, xylene, etc. can be used to wipe the mold.

2.4 Precautions for liquid silicone curing

- The curing chemical reaction of liquid silicone requires a certain reaction time.

- The ideal flow field is in a 2mm diameter and 170cm length runner, and the flow distance can exceed 100cm.

- The minimum thickness is 1/1000mm.

- Excessive mold temperature will lead to early curing, thereby causing blocked flow.

- Laminar flow can avoid the generation of bubbles.

- High-speed injection will lead to the generation of turbulence.

- The viscosity of the material will change the flow pattern.

- Turbulent flow is prone to cause white spots.

3.Conclusion

The injection molding process of liquid silicone requires a basic understanding of liquid silicone, and appropriate and correct design and planning in product design, mold design, and production processing, in order to better understand the design principle of the liquid silicone molding machine and fully cooperate, minimize possible product problems during processing, improve production efficiency and quality.

The injection molding process of liquid silicone has high economic benefits and relatively simple operation difficulty. Moreover, as the demand for liquid silicone products in the industry is also increasing, it means an increase in investment in the talent market, and the market development under a virtuous cycle is becoming more and more vigorous.