Mould manufacturing

We are a reliable partner.

Jvtech is a manufacturer that can provide you with a one-stop solution for liquid silicone parts. We provide customers with support and share valuable opinions in the early stage of design to optimize the design of manufacturing parts and improve product performance. As an extension of your engineering team, our engineers will cooperate as soon as possible to fully understand your products and their components.

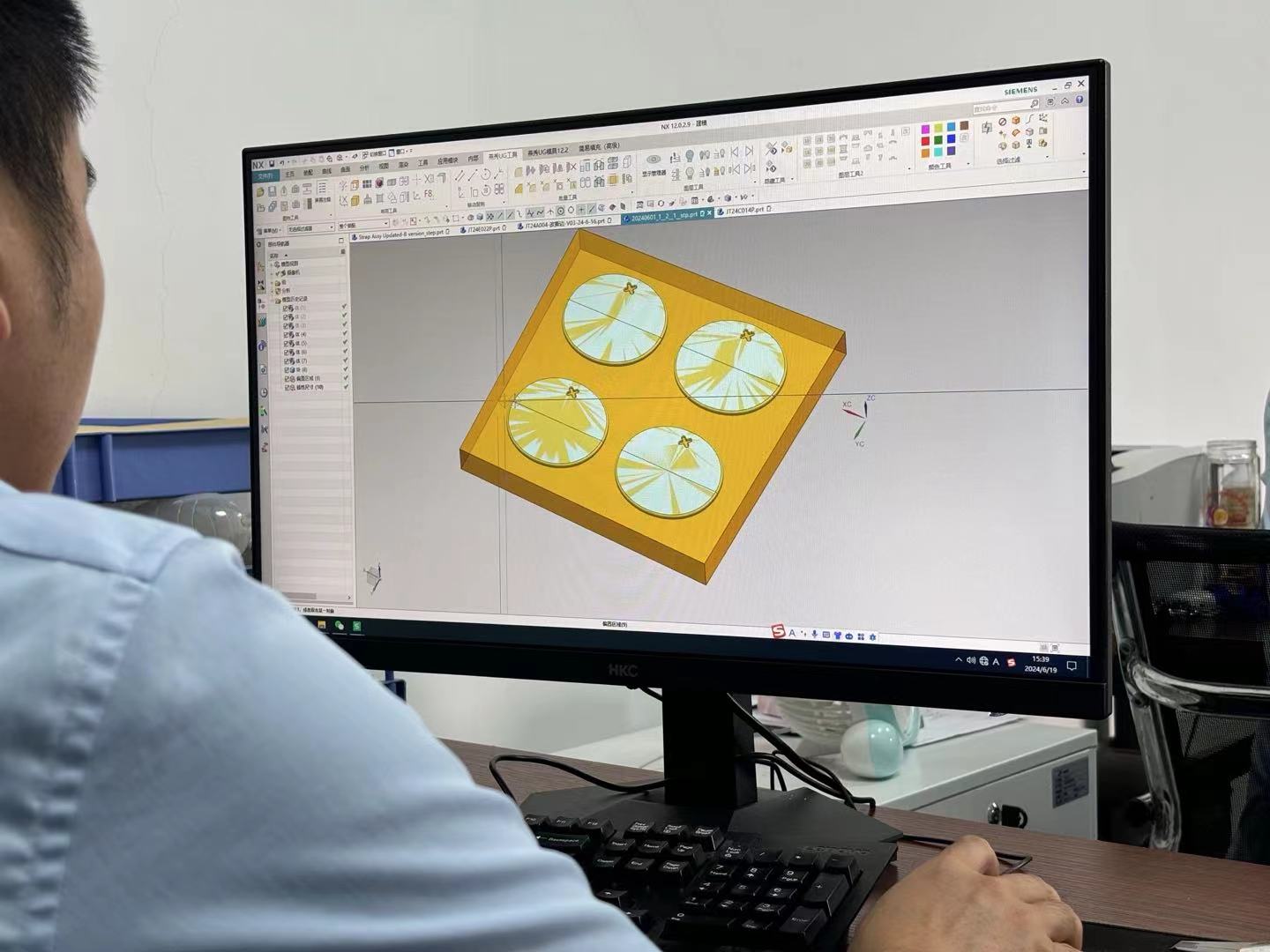

Design stage is the first stage of product development and an important step to ensure the quality of parts production and product performance.

An important consideration of part design optimization is DFM (Manufacturing Design). This method takes into account the properties of liquid silicone rubber and liquid injection molding process. We recommend the most suitable LSR molding process for you, including precision molding, 2k molding, multi-cavity molding and overmolding.

Jvtech combines advanced mold simulation technology with decades of LSR injection expertise, thus enhancing the design of parts, optimizing the molding process, and striving to get it right at one time!

How it works

Easy step

Our international team of engineers works with you to make your product ideas a reality through manufacturing technologies.

Upload Desgin

Submit the important details about your project.

DFM Review

We perform a design analysis to optimize your parts.

Confirm Quote

We begin working with our team to make your ideas a reality.

Production Starts

Your custom parts are delivered straight to your doorstep.

Low cost and rapid verification of product structure feasibility

Prototyping

For complex and key parts design, prototype design may be an important step in product development and manufacturability. This prototype allows companies to evaluate and test part designs before entering full-scale mass production.

We have an independent mold room that allows you to make experimental molds quickly. Click to view equipment list.

Performance and functional testing or clinical testing are key requirements of various industries. The type of LSR rapid experimental module depends on the specific technology used in its production. Choosing a prototype production method depends on answering the following questions:

- What kind of appearance and dimensional quality do you need?

- How many prototype parts do you need and the project delivery time?

- What product features do you need to verify?

Project insight

Core Service

LSR/LIM Injection Molding

LSR molding is different from solid compression molding, with fast productivity and high precision. We also support multi-cavity mold design.

LSR 2K Molding

Jvtech has years of experience of producing multi-component molds and parts (2K or more).

Overmolding

We have a stable R&D process for multi-cavity molds to minimize your production costs.

Quality System

Strict implementation of ISO system standards, professional testing equipment to control product quality.

Volume Production

24-hour operation dust-free production workshop equipped with robotic pick-up, intelligent material storage system.

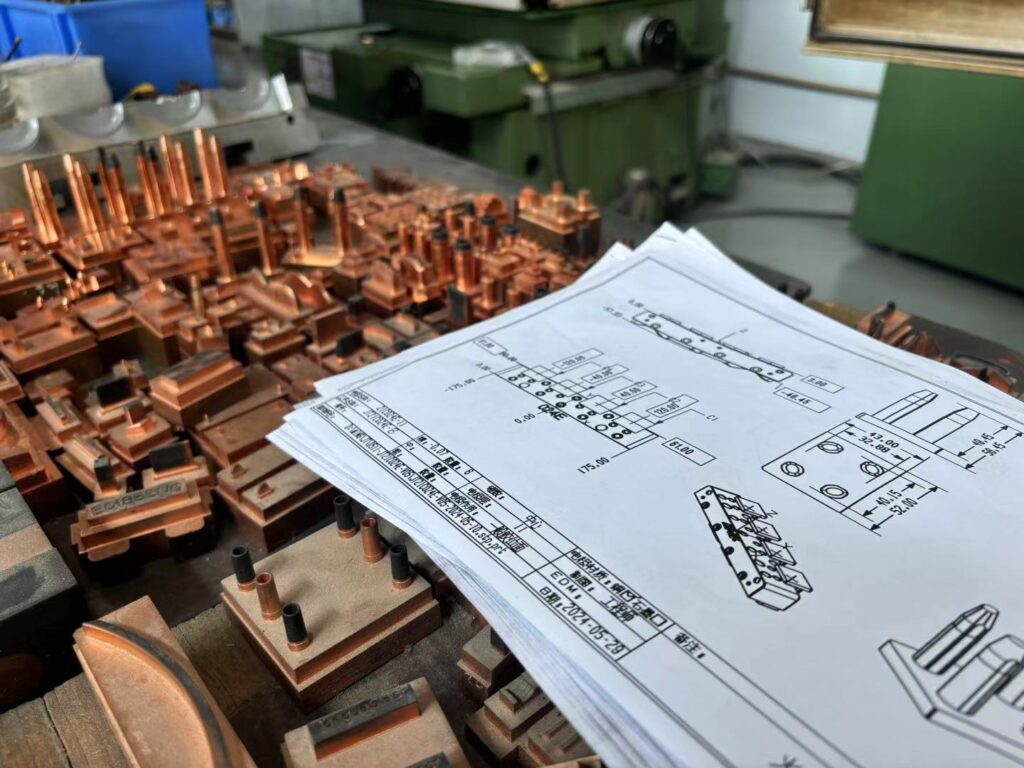

Mould Manufacturing

Support rapid mould, accurate mold flow analysis, and quickly enter according to DFM documents.

Stage T0.

Let's start your project to be realize.

We have a complete service portfolio aimed at supporting customers’ needs. Whether it is DFM advice (which can help you mass-produce large quantities of parts efficiently and economically), selecting suitable raw materials for your project, or simplifying and improving the quality of your supply chain, our expert team will help you at every step.

Trusted by some of the most famous OEM and OEM parts suppliers, we know how to optimize the manufacturing process and maximize the output while still maintaining one of the lowest defect rates in the industry.