On-demand Liquid Silicone Rubber Injection Molding

Custom injection molding for liquid silicone prototypes and on-demand production parts in as fast as 1 day.Request an injection molding quote today.

Certifications

ISO 9001:2015 ▏ISO13485 ▏ISO45001 ▏ISO14001 ▏IATF Registered

3.8 Million

Parts Molded each month

30,000+

Product developers served

50+

Innovative patents

On-demand Liquid Silicone Rubber Injection Molding

Custom injection molding for liquid silicone prototypes and on-demand production parts

in as fast as 1 day.Request an injection molding quote today.

ISO 9001:2015 ▏ISO13485 ▏ISO45001 ▏ISO14001 ▏IATF Registered

Characteristics of Liquid Silicone Rubber

Under extensive tests, liquid silicone rubber has manifested outstanding compatibility with human tissue and body fluids, and it is hypoallergenic, thereby making it an excellent option for skin-contact products. In contrast to other elastomers, liquid silicone rubber is resistant to the growth of bacteria and will neither stain nor corrode other materials.

LSR is tasteless and odorless and can be formulated to meet the strict FDA standards necessary for food and beverage as well as baby products.

Compared with other elastomers, molded silicone is capable of withstanding a broad spectrum of temperature extremes, from high to low. LSR will retain its properties in extreme temperatures ranging from minus 60 degrees Celsius to 180 degrees Celsius. LSR can be discovered in applications such as dishwashers, showerheads, faucets, and hot water heaters that encounter a variety of hot and cold temperatures.

Liquid silicone rubber also possesses excellent insulating properties, which is beneficial for a multitude of electrical applications, including the rapid growth in EV battery applications. Compared with conventional insulating materials, silicone can function at far higher and lower temperatures.

Transparency and pigmentatio,Durable,Mechanical properties,etc. You can click here to get more.

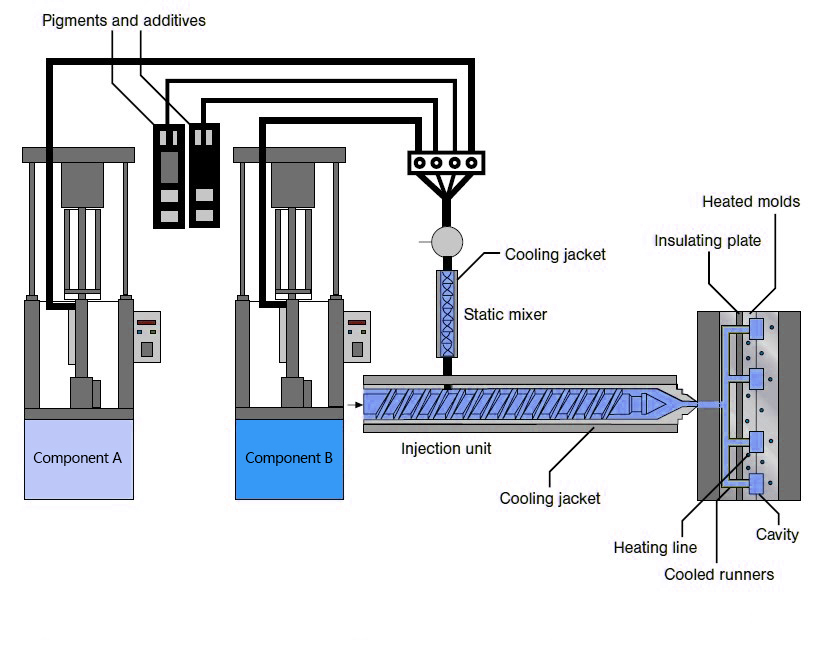

LSR Molding Process

Liquid silicone is usually composed of Component A (including silicone polymers, fillers, etc.) and Component B (including cross-linking agents, catalysts, etc.).

Component A and Component B are precisely mixed in a certain proportion. Under the action of the catalyst, the cross-linking agent reacts with the silicone polymer, converting the silicone from liquid to solid and forming a cross-linked structure, thereby increasing the strength and stability of the material.

Liquid silicone has a low viscosity and can flow and fill well in the mold. During the molding process, conditions such as temperature and pressure will affect the curing speed and the performance of the final product.

- Product Precision

Liquid silicone has good fluidity and can fill complex and fine mold cavities, thereby producing products with high precision and high complexity. Solid silicone is relatively weak in this aspect. - Production Efficiency

Liquid silicone molds can achieve automated production, and its curing speed is relatively fast, resulting in higher production efficiency. In contrast, the production efficiency of solid silicone is lower.

Who we are

One-stop liquid silicone mould & final products manufactuer

Our liquid silicone rubber (LSR) molding process can produce customized prototypes and final product parts in 30 days or less. We use China’s high-quality S36 to provide economical and efficient processing and accelerated manufacturing cycle, and reserve LSR materials of various grades and hardness.

- On-demand production

- Offer DFM report without charges

- Quick delivery

- Wide range of Surface Finish Options

What we do

We made the world with LSR technology

01.

Medical

01. Medical

We are highly capable of providing superior-quality and exceptionally precise products to our esteemed customers within the Medical Device industry.

Learn more 02.

Automotive

02. Automotive

We follow industry standards to ensure precision and quality in every detail to meet the automotive industry's high requirements for complex components.

Learn more 03.

Healthcare

03. Healthcare

Liquid silicone has excellent high temperature resistance and biocompatibility, does not contain harmful substances, and can provide the most comfortable and safe product experience.

Learn more 04.

Consumer

04. Consumer

Multi-component injection molding and offer significant potential and opportunities for innovation and development in 3C&Smart Tech products, providing consumers with more diversity and functionality.

Learn more 05.

Babycare

05. Babycare

Jvtech's professional liquid silicone injection molding and mold manufacturing is one of the important technologies in the production of health care and maternal and child products.

Learn more 06.

Industrial

06. Industrial

Jvtech provide customers with customized services, according to the needs and requirements of customers, tailored to meet their needs of industrial products.

Learn more china JVTECH SILICONE

What we provide..

LSR MOLDING

The chemical characteristics of liquid silicone gel are stable, and the liquid shape can form complex shapes.

LSR 2K MOLDING

2K molding can be combined with two different materials of silicone molding, which can make your product unique,etc.

LSR OVERMOLDING

Because of its stable characteristics, silicone can be wrapped with metals, plastics, glass and other materials.

Exprienced

Since 2010, we have been manufacturing liquid silicone molds in China.

Precision

LSR mo is compl we vigorously introduce technical talents to specialize in design and manufacture.

Win-win cooperation

Invest 45% profit in automatic machines every year, so that your products can not only maintain stable and high-quality mass production, but also greatly reduce labor costs.

Service | Details |

Lead time: | The prototype can be completed in 3 days at the earliest, and the normal completion cycle of the volume production mold is 25 days. The production cycle of products is about 21 days, which should be evaluated according to the product structure. |

Machines available: |

|

Insepection and Certification : | Includes ISO9001 ISO13485 ISO45001 ISO14001,IATF 16949 registered and 6 Medical clean room. |

Cooperative supplier:

| WACKER,ELKEM,SHINETSU,YASDA,KRATON

|

Service industries: | Medical, Maternal and child, Auto parts, Electronics, Industry. |

Quality Inspections

When requesting a quote for your silicone rubber parts, you can select from the following options depending on your application’s requirements:

Quality Inspections for On-Demand Manufacturing Orders

- Design for Manufacturability (DFM) Feedback

- Scientific Molding Process Development Report

- In-Process CMM Inspection and Machine Monitoring

- First Article Inspection (FAI) and Process Capability Report with GD&T

Finishing Options

Jvtech provides customers with post-molding operation solutions after parts are molded.

We are equipped with laser engraving, machining, screen printing, UV, laser cutting and other non-standard equipment.

For large-batch, long-term projects that require LSR components, you can trust Jvtech. We provide solutions for all stages of production, from design and prototype support to production. Our decades of comprehensive experience, advanced technology and strong quality system have made us a leading position in the industry.

How it works

Easy step

Our international team of engineers works with you to make your product ideas a reality through manufacturing technologies.

Upload Desgin

Submit the important details about your project.

DFM Review

We perform a design analysis to optimize your parts.

Confirm Quote

We begin working with our team to make your ideas a reality.

Production Starts

Your custom parts are delivered straight to your doorstep.

Let's start talking with us

Our value

Let’s build the future with innovation.

Jvtech has a team of experienced and skilled designer, engineer and technician. High quality standard, competitive price, on time delivery and responsible afer-sales service are the principle that we follow to develop the mutual trust and confidence with our domestic and international clients.

If you have any new design of products need to be tested and put on the market, please do not hesitate to contact us. We will get back to you as soon as possible.

Professional Expert

Technology & Innovations

Premium Support

About LSR molding, you might want to know...

What is LSR molding (or liquid silicone rubber molding, LSR moulding)?

LSR molding is a manufacturing process that uses liquid silicone rubber (LSR), a two-part thermoset material, to create complex and precise parts. The liquid silicone is injected into a mold, where it cures and hardens into the desired shape.

What are the advantages of LSR molding over other types of molding?

LSR molding offers several advantages, including:

High precision: LSR can be molded into intricate shapes with tight tolerances.

Biocompatibility: LSR is safe for medical and food-contact applications.

Durability: LSR parts are resistant to heat, chemicals, and UV light.

Flexibility: LSR can be formulated to achieve a wide range of hardness and flexibility.

High precision: LSR can be molded into intricate shapes with tight tolerances.

Biocompatibility: LSR is safe for medical and food-contact applications.

Durability: LSR parts are resistant to heat, chemicals, and UV light.

Flexibility: LSR can be formulated to achieve a wide range of hardness and flexibility.

What are the typical applications of LSR molding?

LSR molding is used in a variety of industries, including:

Medical: Implants, medical devices, drug delivery systems

Automotive: Seals, gaskets, O-rings

Electronics: Connectors, keypads, LED lenses

Consumer goods: Kitchenware, baby products, sporting goods

Medical: Implants, medical devices, drug delivery systems

Automotive: Seals, gaskets, O-rings

Electronics: Connectors, keypads, LED lenses

Consumer goods: Kitchenware, baby products, sporting goods

What are the challenges of LSR molding?

LSR molding can be challenging due to:

Material sensitivity: LSR is sensitive to moisture and contaminants, which can affect its cure and properties.

Mold design: LSR molds require careful design to ensure proper filling and venting.

Process control: LSR molding requires precise control of temperature, pressure, and injection speed to achieve consistent results.

Material sensitivity: LSR is sensitive to moisture and contaminants, which can affect its cure and properties.

Mold design: LSR molds require careful design to ensure proper filling and venting.

Process control: LSR molding requires precise control of temperature, pressure, and injection speed to achieve consistent results.

How is LSR molding different from traditional silicone rubber molding?

LSR molding differs from traditional silicone rubber molding in several ways:

Material form: LSR is a liquid, while traditional silicone rubber is a solid or paste.

Processing: LSR is injected into a mold, while traditional silicone rubber is typically compression molded.

Cure time: LSR cures faster than traditional silicone rubber.

Material form: LSR is a liquid, while traditional silicone rubber is a solid or paste.

Processing: LSR is injected into a mold, while traditional silicone rubber is typically compression molded.

Cure time: LSR cures faster than traditional silicone rubber.

How do I choose an LSR molding supplier?

Experience: Look for a supplier with experience in LSR molding and your specific application.

Capabilities: Ensure the supplier has the equipment and expertise to meet your production needs.

Quality: Ask about the supplier's quality control processes and certifications.

Cost: Get quote from Jvtech to ask for reasonable price.

Capabilities: Ensure the supplier has the equipment and expertise to meet your production needs.

Quality: Ask about the supplier's quality control processes and certifications.

Cost: Get quote from Jvtech to ask for reasonable price.