What Is LSR Overmolding?

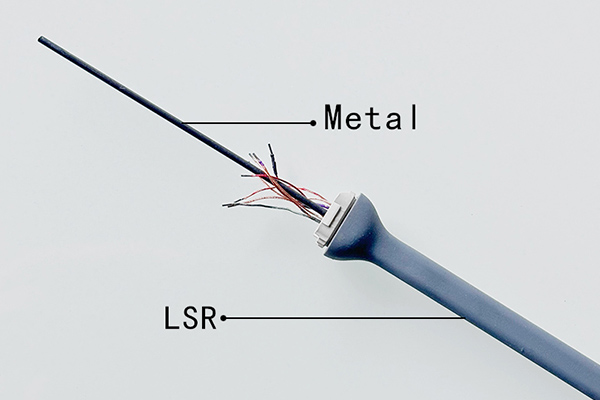

The LSR overmolding process allows manufacturers to produce specialized components consisting of two different substrates. Unlike LSR 2-shot molding in which both materials are molded during the same molding process, in the LSR overmolding process, LSR is molded around a finished molded part, or a metal or other substrate.

Jvtech’s Overmolding Process

Jvtech’s LSR overmolding process is a two-step process:

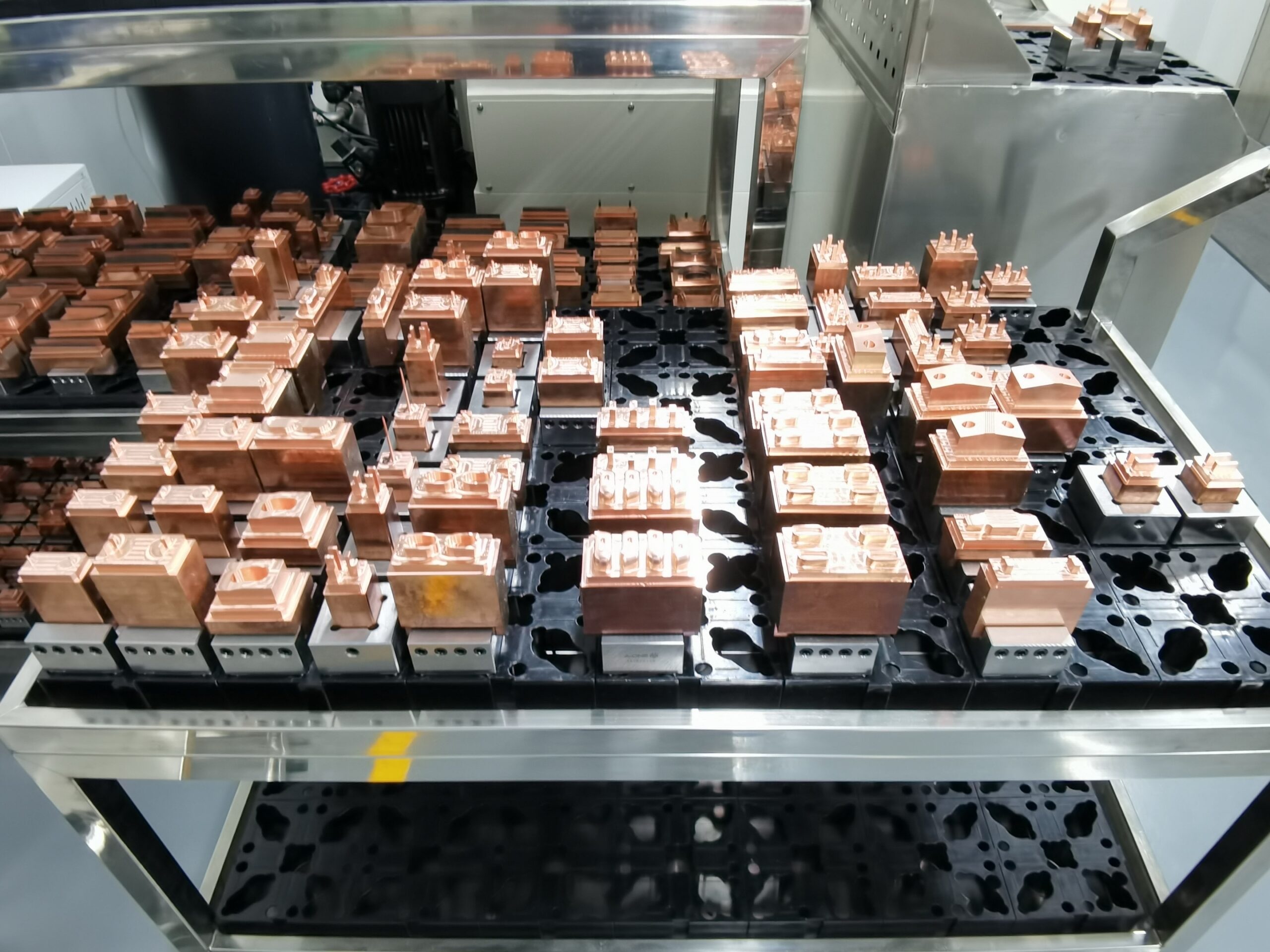

Step one: The finished plastic or metal substrate is robotically placed into the cavity of the specialized LSR mold.

Step two: The mold closes initiating the injection of the LSR material into the cavity, the LSR fills the designated area of the substrate to form a complete LSR integrated component.

Benefits of LSR Overmolding

Benefits & characteristics from both materials: Overmolded components exhibit the characteristics and benefits of both materials – such as rigid and flexible, sealing, and insulating.

Use of Non-plastic substrates: Overmolding is the only way to incorporate substrates, aside from other thermoplastic and elastomer substrates, in the LSR injection molding process.

Cost and time savings: Molding silicone rubber directly onto a metal or plastic substrate eliminates the need for secondary post-molding assembly processes, and saves the associated costs and time for completed assembly.

Design flexibility: By incorporating silicone rubber in the plastic or metal part design, it produces parts that are waterproof, airtight and more resistant to shock and vibrations.

Quality: The accuracy and control in a stable LSR molding process yields precision, high-quality, securely bonded parts and mitigates the risk of seal displacement.