What Is LSR overmolding?

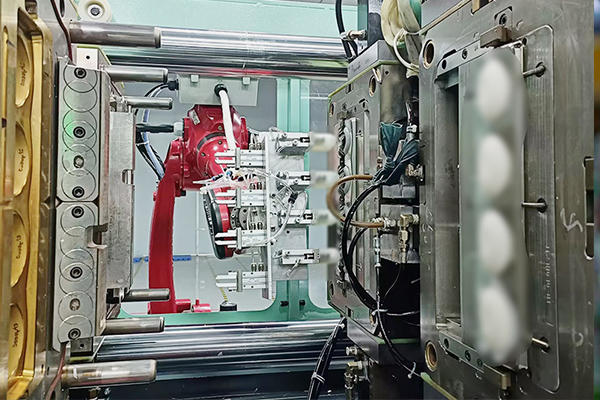

The LSR overmolding process allows manufacturers to produce specialized components consisting of two different substrates. Unlike LSR 2-shot molding in which both materials are molded during the same molding process, in the LSR overmolding process, LSR is molded around a finished molded part, or a metal or other substrate.

When is LSR Overmolding best?

Liquid silicone overmolding produces components with valuable properties, making it ideal for many different industries. Common applications for LSR overmolding include:

Life Sciences

LSR has a long list of desirable characteristics, such as being highly biocompatible, hypoallergenic, odorless and tasteless. These properties are crucial to the medical and life sciences industry, especially when manufacturing items such as respiratory devices, surgical devices, wearables, IV, and syringes and others that must be sterilized. The medical industry also relies on LSR overmolding for LSR grips for stainless steel instruments and hand-held devices.

Automotive

Liquid silicone rubber overmolding offers automotive manufacturers temperature-resistant seals for engine components, headlights and electric connectors. These silicone rubber seals also keep water away from electrical systems throughout the vehicle. LSR overmolding is used for incorporating seals to connectors and other plastic components requiring LSR seals.

Consumer Goods

Since LSR can withstand constant exposure to cleaning products, water and other environmental elements, and has electrical insulation properties, it is a suitable material for a wide range of consumer products, including shower heads, electronic devices and dispensing valves. LSR overmolded components are utilized in consumer electronics, food and beverage dispensers and preparation products, beauty and cosmetic products, and many others.

Industrial and Special Applications

LSR components can operate and endure high temperatures and pressures, allowing industrial manufacturers to use LSR overmolding for seals and gaskets in demanding systems such as water heaters and furnaces. LSR overmolding is ideal for parts with tight tolerances since it can yield precise results.

Jvtech’s overmolding technology offers several significant advantages in the field of lsr manufacturing:

1.Product enhancement

2.Process integration

3.Design flexibility

4.Improved bonding strength

5.Reduced long run production cost

6.Waste reduction

7.Better material variety