Characteristics of LSR

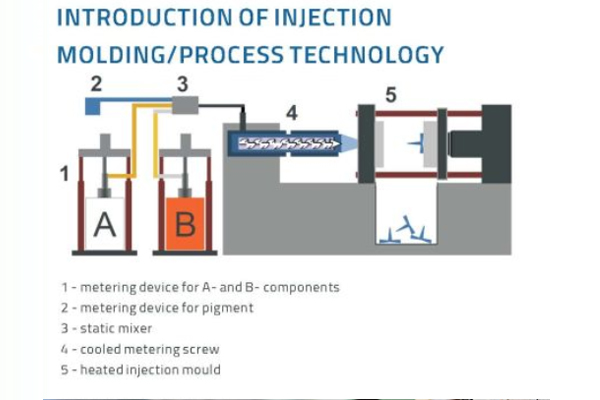

Liquid silicone rubber is high-purity platinum cured silicone. LSR’s physical, chemical and thermal properties make it highly suitable for products where performance, durability and high quality are a necessity.

What can we offer you?

Cooperation with Jvtech for injection molding of liquid silicone rubber can bring many benefits to your company. Our mold design, automation, LSR molding technology and expertise enable us to mass-produce precision customized LSR value-added components.

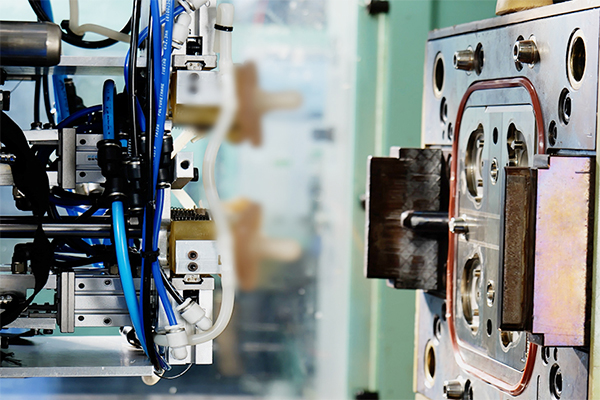

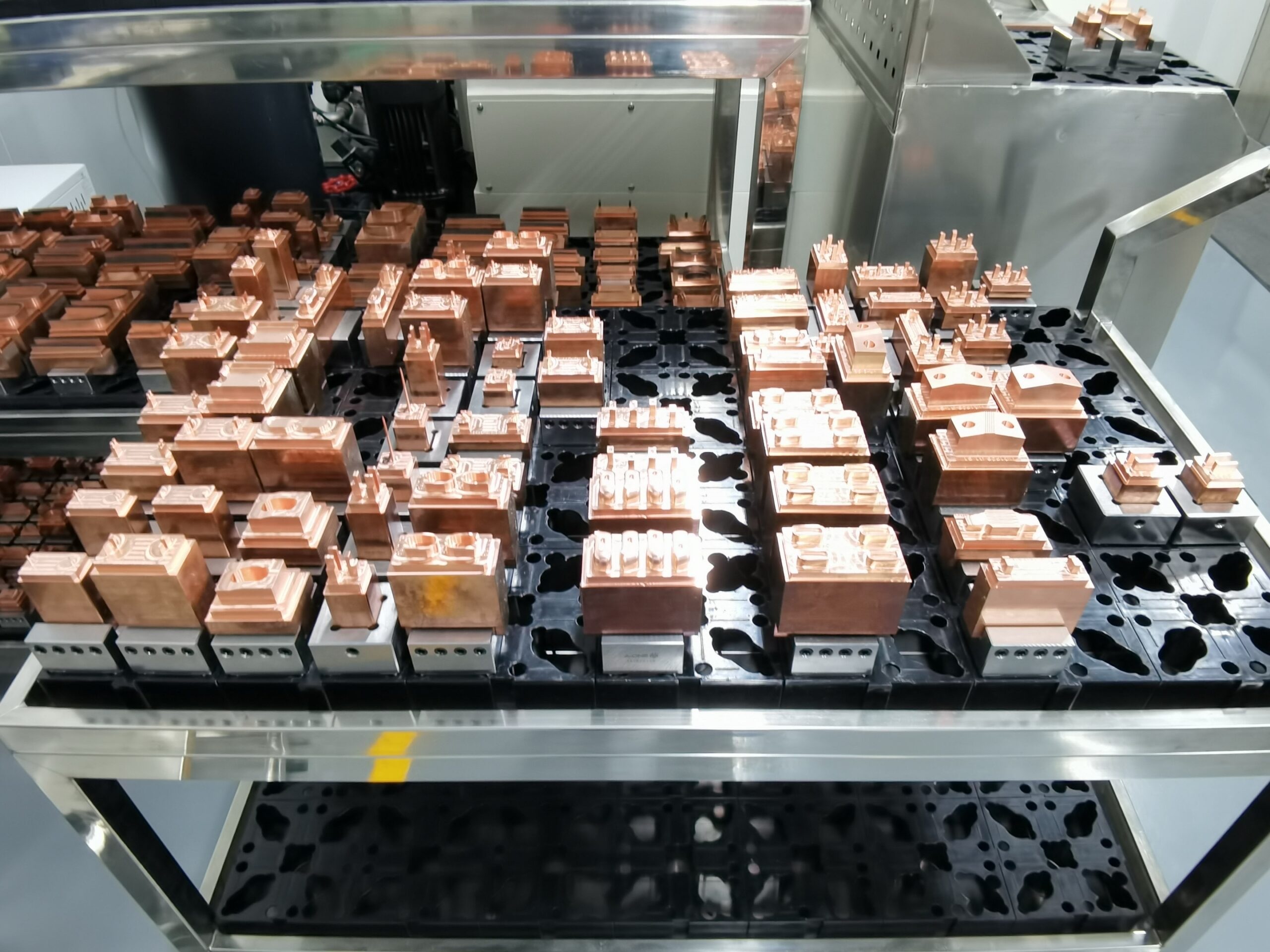

As the leader and pioneer of this industry in China, we are familiar with LSR. There are 60 sets 80-160T injection molding machines. Our production process is highly automated, stable and efficient, specially designed for mass production of precision, small and micro parts.

We offers several options for LSR part production. We carefully evaluate each project to determine the best LSR injection molding technology for producing the components: LSR, LSR multi-cavity, LSR multi-component, or LSR overmolding.

High precision

Reduced flash and waste

Multi-component and overmolding capabilities

Shorter cycle times

Consistent quality