About Us

Our Value

Let’s build the future with innovation.

Vision

With well-founded expertise and cost-effective technology

Mission

All-out efforts to promote automation and move towards the industry's leading level

WHO WE ARE

who we are

JVTECH was established in 2012 and is located in the beautiful Zhongshan City with convenient transportation.We are a manufacturer specializing in silicone solutions.Core services LSR molding, multi-component, multi-cavity, solid compression. And equipped with perfect secondary processing technology.

Equipped with 100,000-class dust-free workshop, laboratory equipped with ROHS, secondary element, CCD, tearing and pulling resistance test, video microscope, VOC detector and other kinds of precision equipment to meet the delivery.

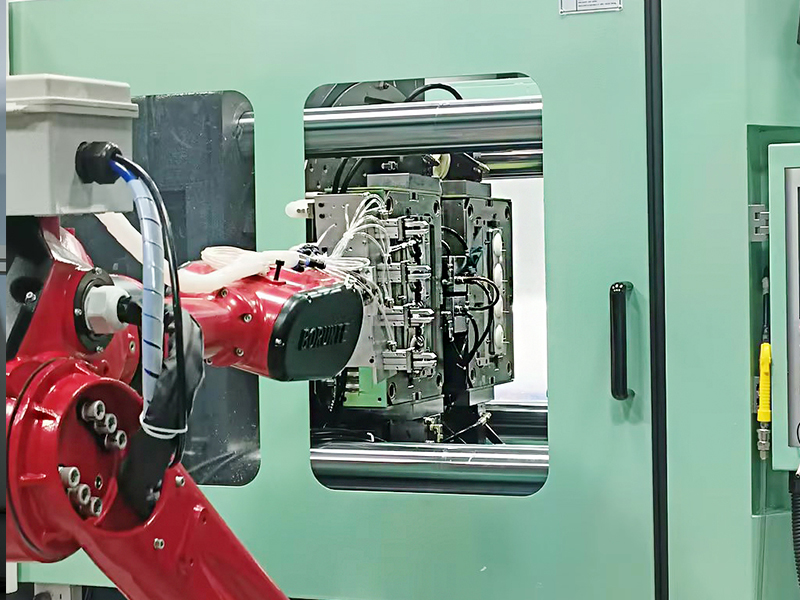

3 independent dust-free production workshops are equipped with 6-axis and 3-axis robots. More than 60 sets of 85-160T LSR injection molding machines and 5 sets of 160T plastic injection molding machines. 2 sets of LSR 2k molding machines.

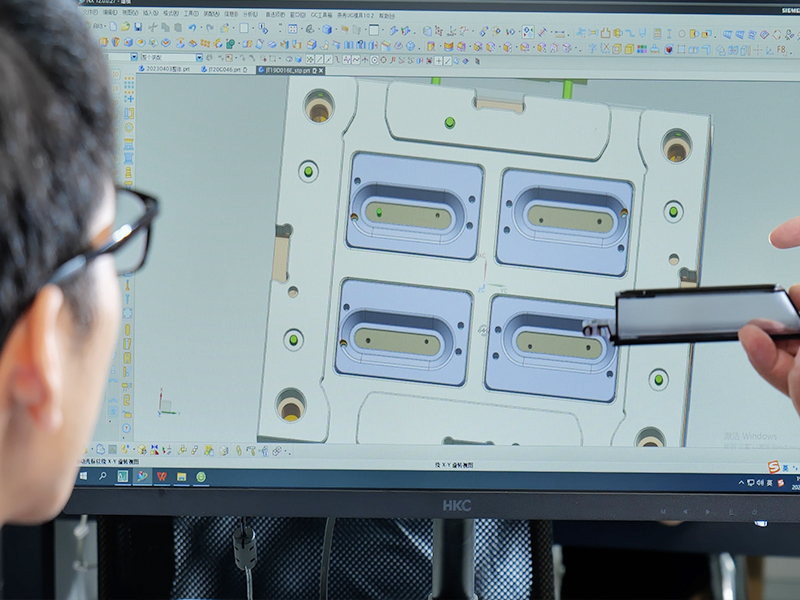

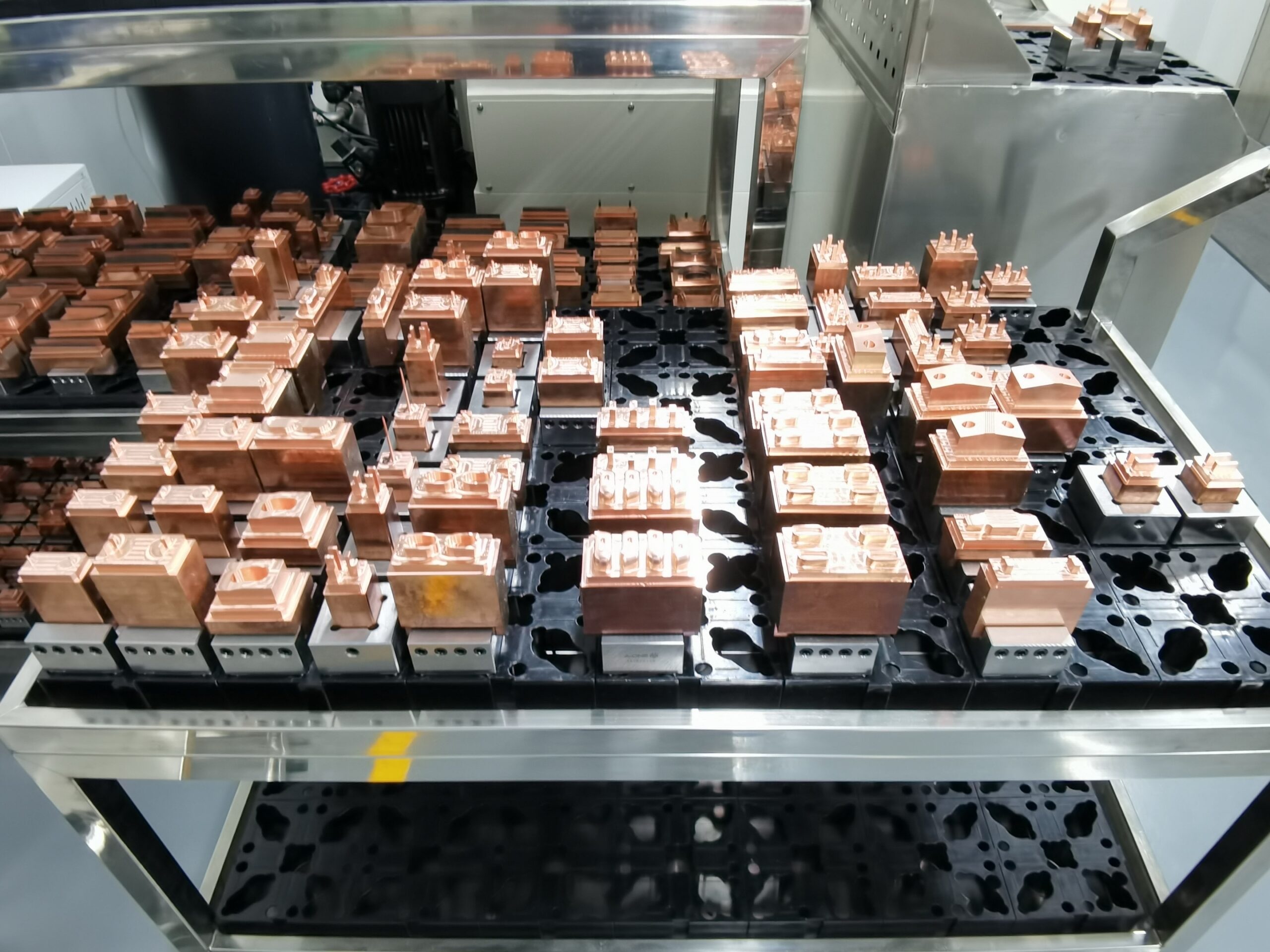

We has set up a design team for professional customer groups, automotive, medical, maternal and child, optical field, DFM assessment and analysis of mold flow and design solutions, mold accuracy is guaranteed to 0.003mm as much as possible to achieve a do it right at the first time, in order to achieve the goal of exceeding customer expectations.

Jvtech Certifications

These certifications demonstrate our commitment to maintaining international standards in operation, product quality and workplace safety, while minimizing the impact on the environment. Click the button below to learn how we control quality.

0

Square meters

0

Founded in

0

+

Patents

0

K+

Project done

Project insight

Core Service

LSR/LIM Injection Molding

LSR molding is different from solid compression molding, with fast productivity and high precision. We also support multi-cavity mold design.

LSR 2K Molding

Jvtech has years of experience of producing multi-component molds and parts (2K or more).

Overmolding

We have a stable R&D process for multi-cavity molds to minimize your production costs.

Quality System

Strict implementation of ISO system standards, professional testing equipment to control product quality.

Volume Production

24-hour operation dust-free production workshop equipped with robotic pick-up, intelligent material storage system.

Mould Manufacturing

Support rapid mould, accurate mold flow analysis, and quickly enter according to DFM documents.

Stage T0.

Our History

2010

Jvtech Precision Mould Processing Department was established.

2017

Jvtech Silicone Technology Co., Ltd. was established.

2022

In order to realize the delivery of 2k,muti-cavity, P+R molding projects for customers.

We expanded to 15,000 square meters, and 2 sets LSR two shot injection molding machines were added.

2024

Jvtech invest 45% of its annual sales profit in automatic production research and development. And expand high-tech industries such as auto parts and optics, and prepare for expanding factories.

Partnering with industry-leading companies

A stable supply chain is what gives your product a competitive edge.

The Factory

Previous image

Next image

Related Article

Let's start your project to be realize.